KEY PERSONNEL:

PROJECT CHALLENGES:

Assembly and use of tower cranes within the site footprint; drainage to include storage tank

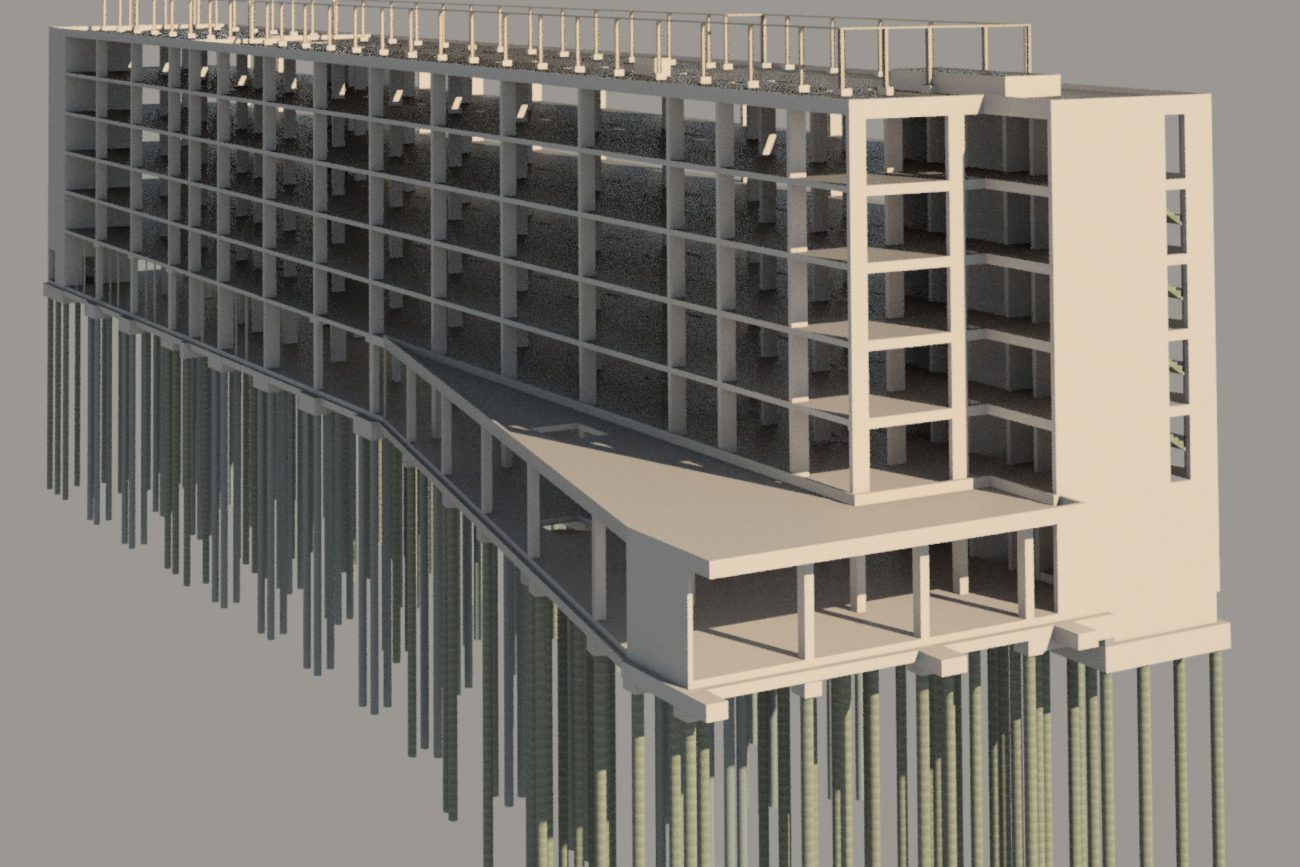

6-storey, 240-bedroom hotel

Constructed in reinforced concrete bearing on augured pile foundations, with a mixture of blockwork, glazing and cladding at ground floor, an insulated steel framing system above first floor, and a free-standing plant enclosure provided to full extent of roof. A grillage of transfer structure was provided at first floor level to create column-free zones around the entrance lobby and reception area. The concrete frame was designed to suit the approved scheme, with future-proof measures taken to accommodate the expected extension. Approval for the extension was received when the original frame was stepped across third and fourth floor, allowing the extension to catch up in phased pours.

The length of the building required two tower cranes to move materials and the tight nature of the site determined that the tower crane bases had to be positioned within the building footprint, with careful planning required for the coordinated sequence of removal and completion of the structural in-fill works. Similarly, the site boundary was a challenge for the drainage network, coupled with level restraints meaning foul water had to be pumped off site and consequent requirement to provide 24-hour emergency on-site storage. This required the construction of a large underground reinforced concrete tank below the surface car parking, sealed from within and without.

(Images from Hampton by Hilton)